![]()

This section was written by Associate Editor Jean Thilmany

computing

The collaborative product definition management

portion of the product lifecycle management market grew 25 percent in 2001

to reach $3.6 billion, according to the consulting and research firm

Cimdata Inc. of Ann Arbor, Mich.

Despite the economic downtown,

companies continued to buy product lifecycle technology during the third

and fourth quarters of 2001, said Ken Amann, Cimdata's director of

research. Product lifecycle management technology allows business to

implement a common business approach and consistent business practices

across the entire organization. It lets users share product information as

they work on design to ensure that everyone involved in the process is

working together using the same information and with the same

goal.

Product definition management is a sector of a product

lifecycle management system that includes everything in that system except

for information authoring tools, such as mechanical and electronic

computer-aided design, computer-aided software engineering, and technical

publishing software. Product definition management focuses on engineers

collaborating, managing, and sharing product information, according to

Amann.

Cimdata forecasts product data management technology growth

to continue at a strong pace over the next five years, to more than $11

billion in 2006.

SMC Corp. of Indianapolis, a maker of pneumatic

automation components, or moving parts, admits it was drowning in its own

product catalogs. The company was producing two million hard copy catalogs

annually.

The catalogs included 8,900 products that could be

configured in 520,000 different ways. The catalogs were expensive to

print, according to SMC officials. SMC publishes an online catalog

for its 8,900 products using 3DpartStream.Net technology.

SMC publishes an online catalog

for its 8,900 products using 3DpartStream.Net technology.

The company recently implemented technology that allows it to publish

an online catalog of parts in a 3-D format. SMC's customers can use the

technology—3DpartStream.Net from SolidWorks of Concord, Mass.—to configure

product models based on their specific requirements and then download the

models into their product design. They can then purchase the actual

components when the product needs to be built.

Beckman Coulter, a

maker of biomedical instruments, uses the technology to select parts for

the more than 40 product designs that engineers develop each year.

Engineers estimate they've shaved about three design days from each

project by using the 3-D Web service.

They used to spend about two

hours modeling parts, using information from the printed catalogs. They

can now insert the models from the online catalogs into a design in

minutes instead of hours, according to a Beckman Coulter statement.

Engineers at Pennsylvania State University in

University Park have developed software to efficiently manage radio

spectrum use to prevent interference on the wireless broadband systems

used for high-speed Internet access.

The finding could bring down

the cost of wireless high-speed Internet, according to Mohsen Kavehrad,

director of Penn State's Center for Information and Communications

Technology Research, where the software was developed.

Currently,

high-speed Internet access capable of carrying MP3 files, video, or

teleconferencing is available mainly over networks connected by wires,

although wireless local loops are being introduced in some test markets,

Kavehrad said. But the wireless networks have to compete for bandwidth

space. They share bandwidth with cordless phones or even radiation from

microwave ovens.

The wireless local loops work much like cell

phones in that they function via a base station that sends the radio

signals carrying the Internet connection to customers who have an

appropriate antenna. But unlike cell phones, the traffic between the

customer and the Internet provider's base station flows unevenly. Like a

highway system, it's used little during sleeping hours and other times are

rush hours, such as when kids come home from school and download music or

play games.

So wireless local loops need software and hardware that

allow the network to respond to changes in traffic and make sure that

every frequency in the spectrum is used efficiently, Kavehrad

said.

The software developed by the Penn State engineers allows a

subscriber whose signal has the least amount of interference to be

processed ahead of signals with strong interference. Because the amount of

interference on any subscriber's signal varies by microseconds, no

subscriber has to wait long for a turn, Kavehrad added.

"With this

technique, service providers could offer quality service to more homes

using only a limited span on the radio spectrum," Kavehrad said. "And if

providers can squeeze more customers onto the available bandwidth, it

could translate into lower costs for the consumer."

John and Brenda Baust run the B&M Toolworks

tool and die shop in Sedalia, Mo. When they started the business out of

their garage in 1995, they added business by word of mouth. They've now

turned to the Internet.

Recently, Brenda Baust discovered that the

company could bid on jobs online. She found it to be a way to look outside

their regular business providers. The company bids on requests for quotes

from around the nation via a Web site called MfgQuote. com, operated by a

Smyrna, Ga., company of the same name. For a fee, the site matches

suppliers with businesses seeking their services. B&M Toolworks has

won business from companies in Colorado, New Jersey, New York, and on the

West Coast, according to John Baust.

He said that the Internet is a new

and growing way for suppliers to answer RFQs.

"I believe this type

of online bidding will continue to grow steadily," he said.

His

business saved money by submitting quotes online because he didn't have to

travel to an original equipment manufacturer to submit the

quote.

Baust said he expects to see about $200,000 in increased

sales this year, thanks to his company's online bidding.

American Stove Parts Co. of San Clemente, Calif.,

makes custom stove parts and parts for original equipment manufacturers,

largely through injection molding. It also assembles metal components for

commercial and domestic stovetops.

Because the company makes many

products of varying quantities, it recently implemented CAD and

computer-aided manufacturing technology that are integrated for

efficiency, according to Everton Cope, the company's president. Before

using the technology, the company got CAD designs from outside vendors or

from its customers' vendors.

Engineers at the company, which

implemented VX CAD and CAM software, now meet with customers to understand

application requirements. They then make three-dimensional models for

customer review. The step has eliminated stereolithography, which can be

costly, Cope said.

In the future, engineers will use the

technology, from VX Corp. of Palm Bay, Fla., to design molds and to send

part files directly to the suppliers who make the molds. The suppliers can

then directly translate the CAM code into their computer numerically

controlled machines, Cope said.

ASML in Veldhoven, the Netherlands, manufactures

machines that make semiconductors. As part of a recent project, engineers

at the company used a software application designed to simplify a

computer-aided design file for thermal analysis. The analysis, carried out

within a separate software application, determined the thermal reliability

of a lithographic system while it was still in the digital stage.

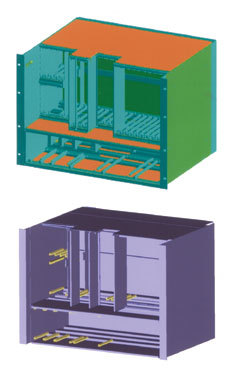

Engineers at ASML used software

from Flomerics to simplify a CAD design of a lithographic system (top) and

then perform a thermal analysis on the design (bottom).

Engineers at ASML used software

from Flomerics to simplify a CAD design of a lithographic system (top) and

then perform a thermal analysis on the design (bottom).

The lithographic, or imaging, system from ASML prints circuit

information on silicon wafers and is used to make integrated circuits. It

allows semiconductor manufacturers to continually shrink designs and

produce more chips per wafer with higher yield and performance. Heat

dissipation is an issue as the number of functions within the system

continues to increase, which means a rise in the number and power of

electrical and heat-dissipating components.

The software

application that enabled engineers to simplify an existing CAD file is

called Flo/MCAD from Flomerics of Southborough, Mass. The software

automatically eliminates intricate details not required for thermal

analysis purposes. The CAD file for the control cabinet of a lithographic

system had been made in Solid Edge from EDS of Plano, Texas.

Before they had the simplifying software, engineers had to rekey

data from the original CAD files into a simplified format prior to thermal

analysis.

After simplifying the CAD design, ASML engineers used

Flotherm thermal analysis software, also from Flomerics, to find out if

higher-power electrical components placed within the system would be

effectively cooled.

The Japanese automaker Mazda has developed new

virtual testing capability to test cars and parts for durability,

reliability, noise, vibration, ride, and handling before they're produced.

The testing software was developed with MTS Systems Corp. of Eden Prairie,

Minn., and two other companies.

As part of a venture called the

Mazda Digital Innovation Project, which began in 1996, the automaker

joined with MTS Systems, MSC.Software Corp. of Los Angeles, and nCODE of

Southfield, Mich., to develop virtual simulation technology in an open

software environment. The project allows test data acquired from

mechanical testing systems to be used in computer simulation and

modeling.

The software developed as part of the project results in

what Mazda calls a virtual testing toolbox, which shortens vehicle

development time because parts can be tested before they're produced,

according to the company.

WMH Tool Group of Chicago has incorporated what's

called project collaboration software to make sure that members of its

design team can access up-to-date information at any time, regardless of

location.

With the technology, Streamline, from Autodesk of San

Rafael, Calif., designers can collaborate online to keep product

development moving at a consistent pace, according to Bill McCann,

technical publications editor at WMH Tool Group. Design team members are

located in the United States, China, and Europe. Because the software

ensures that members are looking at the most recent design changes, it

helps reduce errors associated with keeping track of files saved on a

server, McCann said.

"With our design team spread among several

locations and working on more than 50 active projects together, it's

crucial to have the information organized and accessible by everyone," he

said.

One of the most difficult parts of

pintle-controlled rocket design is configuring the nozzle so the gas

pressure at the nozzle exit equals the outside air pressure in order to

maximize thrust, according to engineers at Stone Engineering Co. in

Huntsville, Ala.

The company carries out propulsion and structure

design for the U.S. Army Missile Command and its Space and Strategic

Defense Command. One of the engineering company's current projects is

designing a bipropellant gel rocket engine that uses an axial pintle to

control the throat area of the engine and thus the motor thrust.

The pintle rocket design helps overcome a basic challenge in

rocket motor design, according to Chuck Margraves, a Stone Engineering

mechanical en- gineer. To keep the pressure of the combustion gases at the

end of the nozzle equal to or close to atmospheric pressure, and thus

maximize thrust, engineers must change the geometry of the nozzle.

Stone Engineering Co. engineers use computational fluid dynamics

technology combined with physical testing rather than physical testing

alone on the current project to determine the best nozzle configuration

for rocket design, Margraves said.

"CFD allows us to look inside

our design to gain a far greater understanding than we were ever able to

achieve with physical testing results alone," Margraves said. "The result

is that we can see exactly where flow separation occurs for various nozzle

geometries and fine-tune our design to maximize thrust under a wide range

of flow conditions.

The company uses Fluent CFD software from

Fluent Inc. of Lebanon, N.H. In a recent experiment, the software analysis

showed engineers the forces acting on the pintle at various flow

conditions. The information helped engineers develop specifications for

the spring that controls the pintle, Margraves said.

A provider of hardware and software, NEC Solutions (America) of Sacramento, Calif., has released PowerMate eco, which is a personal computer with no boron in the monitor, lead-free solder, and recyclable plastic. The computer also has no fan to disperse hazardous dust and contains no other dangerous chemicals, according to an NEC statement.

CFX of Waterloo, Ontario, a maker of computer-aided engineering software, has released CFX-5.5.1, the latest version of the company's computational fluid dynamics software.

Resinate Corp. of Andover, Mass., a provider of automated materials management software for discrete manufacturers, has released its software application Resinate Material Advisor/Plastic version 3.0.

Spatial Corp. of Westminster, Colo., a maker of 3-D development software, recently released two new products, 3D InterOp Exchange and 3D Viz Exchange. The two have been released as separate components within Spatial's InterOp product line.

Coade of Houston, a maker of engineering software, has released Caesar II version 4.40, an updated edition of the company's software for pipe stress analysis and design. Enhancements include updates to piping code and an intelligent hydrostatic load analysis.

Proficiency of Marlborough, Mass., which makes engineering supply chain collaboration software, has announced a partnership with PTC of Waltham, Mass., which makes CAD, PDM, and other engineering software. Proficiency's Collaboration Gateway software allows collaboration on the design of products without the need for trans- lation software, such as standard for the exchange of product model data (STEP).

NavisWorks Ltd. of Sheffield, England, a developer of interactive viewing technology and of 3-D design review software, has released an upgrade to NavisWorks. Version 2.2 of the software works with Windows XP and includes upgraded features to aid collaboration.

Alibre of Richardson, Texas, has created a program for value-added resellers to sell Alibre Design, the company's application for 3-D design, collaboration, and data sharing.

Delcam of Birmingham, England, a maker of manufacturing and engineering software, has released a new version of its PowerInspect software, which will support the inspection of models against simulation and test language (STL) files.

home | features | news update | marketplace | departments | about ME | back issues | ASME | site search

© 2002 by The American Society of Mechanical Engineers